.net

| Terms of service | ||||

|

Brokking |

.net |

Let's keep it simple |

|

|

|

Reflow soldering hot plate

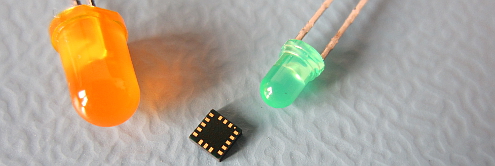

Most Standard smd or smt components can easily be soldered with a soldering iron. Especially when working on a prototype. The pain begins when you start using small lga sensors like this. With a 3x3x1mm package size these things are tiny.

I use these sensors for my multicopter projects and they need to work flawlessly. Crashing due to a defect sensor is not my idea of fun. To get the maximum performance and reliability I was looking for an easy way to solder these sensors. Soldering them with a soldering iron will cause mechanical stress that reduce the reliability significantly. With a heat gun the temperature profile is hard to control and there is no way to check the quality of the solder joints. Mounting it dead bug style is the only reliable way to solder a lga component like this with a soldering iron. Of course you still need to respect the moisture sensitivity level. But it is possible: So what I needed (or wanted) was a fully temperature controlled reflow tool that does the job hands-off. After some research between a toaster oven and a hot plate I went for the hot plate. Mechanically easy, small, lightweight, and in my personal opinion a good way to transfer heat.

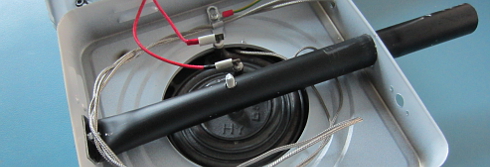

To make it a hands-off tool I needed to find a way to cool the plate when the reflow soldering job is done. After some thinking I came up with the 100W blower that I use to inflate our sons pool. To get a good and reliable temperature reading I went for three thermocouple sensors. This way I can easily check the workings of the sensors and guaranty a good temperature profile. In my opinion this is important when you solder critical components. And it is working perfectly. The only unexpected part was the enormous cold spot on the plate. Luckily I used 3 thermocouples so the difference in temperature immediately showed up. The only downside is that I cannot use the complete hot plate surface. Well, I can live with that and I'm very happy with the results so far. |